|

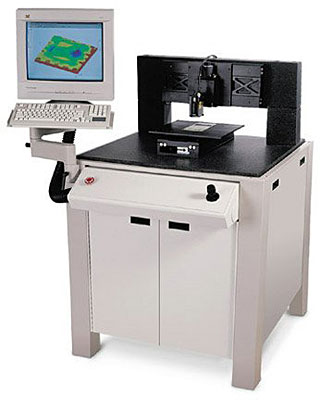

Automated surface

inspection with the AutoScan 3D

measurement system

The AutoScan

surface inspection system is an addition to

Solarius' industry proven 3D measurement tools

based on laser inspection technology. It allows

for fully automated measuring sequences through

an easy to use Active X environment and was

especially designed for use in high volume

off-line production and QC environments.

The AutoScan

delivers sub-micron resolution in all axes and

has flexible system designs depending on

individual application needs. Stage

configurations start at 300 mm (12"), larger

systems comprise stage sizes up to 600 mm (24").

This makes the AutoScan surface inspection tool

ideal for highly precise and automated 3D

measurement of larger surfaces or groups of

parts.

Employing a very

powerful analytical software tool (SolarScan),

the AutoScan features detailed surface form and

finish analysis supported by high-resolution

graphics. The user interface is highly

configurable, in terms of the data displayed and

operator interaction.

The AutoScan comes

with the option of two confocal laser point

sensors: the LT8010 and the LT8110. Both laser

inspection techniques allow macro- and

microstructures of soft and touch-sensitive

surfaces to be quantified without damaging the

sample.

Standard

components

- Sensor

system

- High

precision motorized x, y-stages

- MS Windows«

2000

Options

- Vacuum

fixture and pump

- Custom

stage configurations

- Custom

fixtures

-

Automated z-axis

-

Advanced analysis software SolarMap

Applications

include

-

Thick Film/Hybrid

-

IC-Packaging

-

Engineering Surfaces

For more information on the AutoScan

surface inspection system, please

download the data sheet. [pdf,

312 KB] |