|

Applications

Thick Film:

Quality assurance in hybrid technology

The task

Thick film printing is one of the most important

steps in hybrid production. In this process,

demand for lower failure rates and higher

robustness of the modules has increased

tremendously. Therefore, in order to meet

present quality standards, highly accurate

measurement of production parameters is crucial.

These include printed resistor layers, conductor

paths and laser trim structures. As of now,

measurement with tactile instruments after the

baking process is still the most common method

to determine these parameters, but it is

time-consuming and depends on the operator who

has to visually analyze the results.

The solution

The LaserScan and AutoScan provide the operator

in production with the ideal tools for thick

film measurement. Their innovative sensors and

modular software concept allow for fast,

automated measurement of film thickness and

other production parameters, including freshly

printed paste. Thereby fast and precise control

of the screen-printing machine is made possible,

as for instance by automatically generating an

SPC chart.

The Viking desktop

tool offers a cost effective solution for mid

range accuracy needs.

The Viking

in the process

of measuring thickfilm |

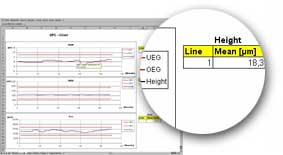

The

LaserScan measures various parameters

such as height, depth, width and angle |

Laser trim

structures on printed resistor |

Automatic

generation of an SPC chart with

height, width and area |

Complex

multilayered structures can be precisely

measured with the LaserScan |

IC Packaging:

Process control for semiconductor back-end

inspection

The task

Modern IC Packaging such as Chip Scale Package

or Flip-Chip advances into new frontiers, with

dimensions that become smaller and smaller. This

development presents new challenges for

production, as warpage and coplanarity problems

can occur. The Chip on Board Technology (COB)

requires spot checks of fine pitch solder.

The solution

The LaserScan enables manufacturers of IC

Packaging modules to analyze warpage, lead

coplanarity, laser marking and contact

roughness.

Solder paste

volume and position can be measured with the

AutoScan platform.

Measurement of spread, coplanarity and

warpage (TSOP- Package) |

Automatic

volume measurement

of fine-pitch solder bumps with

LaserScan |

Adhesive

dots for microwave modules, measured

with LaserScan |

Tribology: 3D

parameters of surfaces

The task

Surface metrology plays a significant role for

the interaction and wear of engineering

surfaces, where not only profile measurement but

also topographical measurement becomes more and

more important.

For this purpose,

new 3D surface parameters are increasingly used

to describe the surface, which presents new

challenges for the resolution and speed of

metrology systems.

The solution

With the confocal microscope Sensofar

topographic 3D measurement

of tribological surfaces has become possible.

Combining these

acquisition capabilities with its data analysis

software for 3D surface parameters, the Sensofar

represents a complete tool for the evaluation of

surfaces in tribology. And to make sure that the

customer‚??s concerns are continuously

addressed, Solarius Development works closely

with competent partners in research and

production.

The Viking profiler allows for measurement of

stress, wear and other form features on both

plastic and metal surfaces.

Honed grooves in cylinder |

Sheet metal after a friction test, 3D

measurement with Sensofar |

Textured sheet metal surface for

the automotive industry, indentations

aid in oil absorption |

Surface analysis software for

calculation of important 3D surface

parameters.

|

|